Transforming the supply chain of future with smart processes

Blog: Capgemini CTO Blog

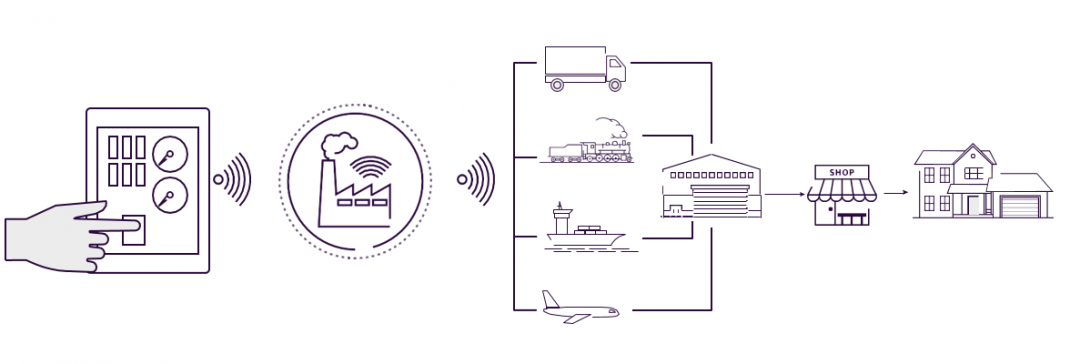

Smart factories and smart distribution centers (DCs) have consistently proven the benefits of synergies between machine learning and business processes. Processes have become more efficient and forward-looking by making intelligent data-based decisions. Smart factories have become an achievable reality much earlier than expected, and dark warehouses (facilities with drone packing and automated picking) are quickly following suit.

Despite these smart segments of supply chain, the following questions remain:

- Have the individual, well-oiled, self-correcting, internet of things (IoT)-enabled machines solved basic business problems? For instance, are there stock outs in one region while surplus inventory in another?

- Does a 4-hour and not 24-hour order-to-delivery cycle truly qualify as a value proposition to retail customers?

- Do we even need micro fulfillment centers, let alone warehouses?

- Do we really need a team of planners to coordinate demand and supply cycles?

Changing the status quo

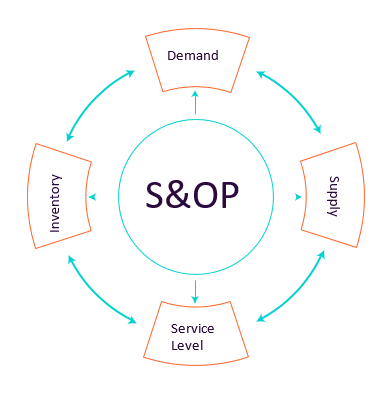

Smart factories and smart DCs have made great strides in how products are procured, produced, stored, and distributed. This has provided strong individual links in our supply chain, but the whole chain can still only be as strong as its weakest link. Sales & Operations Planning (S&OP) is the process that connects various supply chain aspects with the business. It still represents an opportunity for improvement. When S&OP lags behind, the whole business lags behind. To revolutionize the entire supply chain, companies will likely need to include a smart, artificial intelligence (AI)-driven process that drives alignment among smart factories, warehouses, inventory planning, and business functions.

S&OP is an integrated process, aligning offer management, supply, and financial planning with customer demand while considering the organization’s growth and profit objectives. Smart S&OP is augmented with machine learning and serves not just to align functions, but also to predict trends and make real-time supply chain changes.

Organizations that are not transitioning from classical S&OP to smart S&OP are failing to reap true benefits from IoT and various disparate datasets they already use. Data and IoT solutions may be fragmented, but most of the data points already exist. For instance, most organizations know their demand inputs and shipping points to service the customers but still struggle in positioning the right inventory, in the right quantity, and at the right location. True value is delivered by connecting these data points to provide one consolidated source of information and decision making. The benefit of consolidating the data, linking segregated machines and datasets, and leveraging them to reconcile, predict, report, and act will revolutionize the supply chain.

Building a cutting-edge supply chain

Each of the five steps of S&OP has the potential to be AI-driven and connected via IoT-enabled machines. They include:

- Offer management

- Demand management

- Supply management

- Integration

- Executive review/reconciliation

These steps need not be based only on statistical models, but could also be constantly forward-looking, predicting trends, and making reconciliations and adjustments in real time.

Today, models based on regression, quantization, and neural algorithms can make predictions that are over 90% accurate. Major automotive manufacturers are incorporating inventory forecast driven by this intelligence. Models would anticipate demand by region and service center based on last service date, average miles driven by customer, average revolutions per minute (rpm), customers’ traveling history, weather conditions, etc. This would make forecasting smart and dynamic with the ability to propose live inventory and stocking changes. On the other hand, e-commerce giants are working with models that predict international transit time based on ocean leg, weather, carrier, lane, region, market trends/promotions, etc. These models would update cargo arrival date, recalculate inventory levels, update ordering quantities and auto adjust trigger to upstream supply chain, thereby delivering predictive transportation control tower with auto track/trace and trigger for upstream supply chain.

No matter the industry, the commonality between these scenarios is the use of advanced algorithms to create robust models to predict future trends with significant accuracy. Using this intelligence with current data points and auto-adjusting supply chain parameters would deliver a smart S&OP process.

Catalyzing a revolution in supply chain

Smart S&OP will make organizations significantly more efficient, effective, and able to respond in real time. A supply chain equipped with a smart factory, a smart DC, and a governing smart S&OP has the potential of automating most segments of the supply chain, by removing human involvement in many repetitive tasks. Manufacturing using robotics, picking-packing using automated systems, and transporting using drones will revolutionize the end-to-end supply chain if properly aligned to an automated S&OP. A matured, smart S&OP process could be well advanced in predicting trends and making real-time adjustments, delivering a state-of-the-art supply chain. This supply chain has the potential to render dark warehouses obsolete and make driver route optimization as archaic as manual planning. A warehouse/fulfillment center/DC simply acts as a buffer for seasonality, spikes, and fluctuations in volume; a matured S&OP process could predict, align and adjust in real time. More resources could further be redirected to a mature drone delivery model, eliminating the need for driver management and road optimization.

In conclusion, to reap the true benefits of individual, well-oiled machines such as smart factories and smart DCs, the supply chain needs a smart S&OP process. Deploying smart S&OP largely depends on datasets already used by organizations, alongside algorithms that best fit respective corporate strategy. Smart S&OP process not only drives business alignment but predicts and proposes adjustments making the supply chain more proactive, and self-correcting.

Pankaj Mathur is an experienced Supply Chain professional in Capgemini and can be reached at pankaj.mathur@capgemini.com

Leave a Comment

You must be logged in to post a comment.