Process innovation framework

Description

The Process Innovation Framework combines the Process Innovation Canvas, the Seven Wastes of Lean, Moments of Truth and Points of Failure with the revolutionary SCAMPER/Process Innovation Matrix to accelerate the improvement of business processes.

Transcript

1 Copyright 2013Craig Paxson

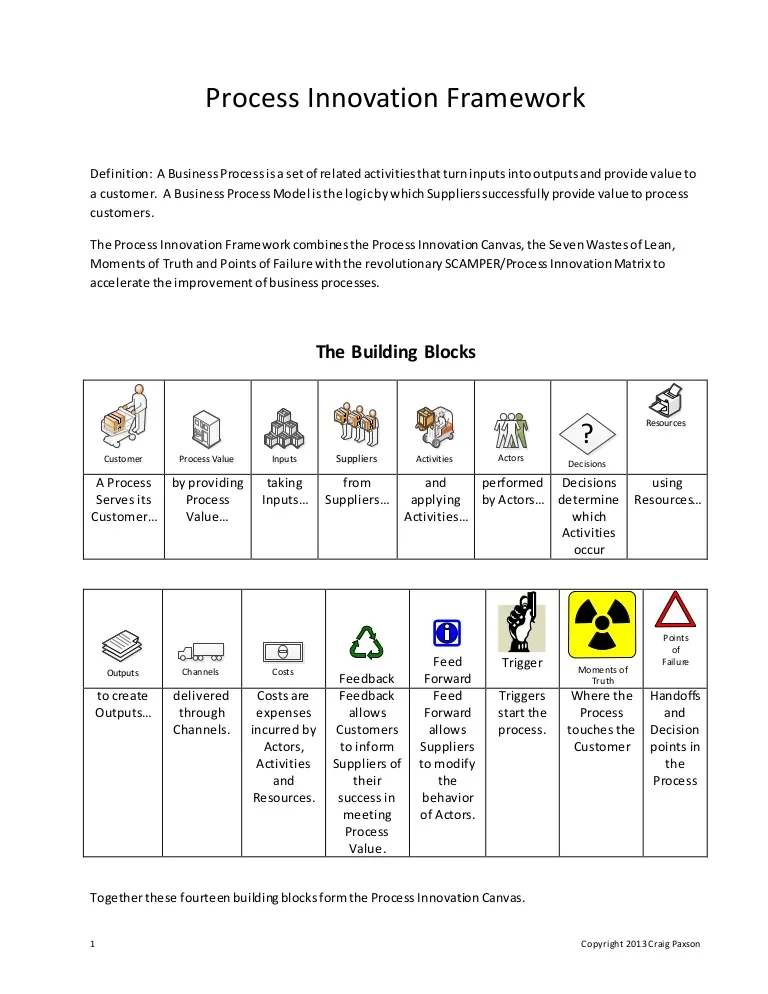

Process Innovation Framework

Definition: A BusinessProcessisasetof relatedactivitiesthatturninputsintooutputsandprovide value to

a customer. A BusinessProcessModel isthe logicbywhichSupplierssuccessfullyprovide valuetoprocess

customers.

The ProcessInnovation Frameworkcombinesthe ProcessInnovationCanvas,the SevenWastesof Lean,

Momentsof Truthand Pointsof Failure withthe revolutionarySCAMPER/ProcessInnovationMatrix to

accelerate the improvementof businessprocesses.

The Building Blocks

CustomerCustomer Process ValueProcess Value InputsInputs SuppliersSuppliers ActivitiesActivities Actors

?

Decisions

ResourcesResources

A Process

Serves its

Customer…

by providing

Process

Value…

taking

Inputs…

from

Suppliers…

and

applying

Activities…

performed

by Actors…

Decisions

determine

which

Activities

occur

using

Resources…

OutputsOutputs Channels Costs

Feedback

Feed

Forward

Trigger Moments of

Truth

Points

of

Failure

to create

Outputs…

delivered

through

Channels.

Costs are

expenses

incurred by

Actors,

Activities

and

Resources.

Feedback

allows

Customers

to inform

Suppliers of

their

success in

meeting

Process

Value.

Feed

Forward

allows

Suppliers

to modify

the

behavior

of Actors.

Triggers

start the

process.

Where the

Process

touches the

Customer

Handoffs

and

Decision

points in

the

Process

Togetherthese fourteenbuildingblocksformthe Process Innovation Canvas.

2 Copyright 2013Craig Paxson

Customers

Inputs Outputs

Feedback

Feed Forward

TITLE DRAWN BY REVISED

Business Process Model

Actors Channels

Costs

Process Innovation Canvas

Process Value

Suppliers

Activities

Resources

Copyright 2012 by Craig Paxson

Points

of

Failure

Moments of

Truth

3 Copyright 2013Craig Paxson

Customer

Everyprocessservesone ormore Customers. Customersare definedasanypeople ororganizationswho

consume,oruse,the product or service the processoutputs.

Customersmaybe internal (existingwithinthe organization) orexternal(existingoutside the organization).

Customersprovide feedbacktosuppliersaboutthe processoutputs. External customersmayuse theirpowerof

choice of not usingthe processto influencethe supplier;internal customersmaynothave a choice,sofeedback

will existinotherways.

Thingsto rememberaboutCustomers:

- Customerscanbe Internal orExternal.

- Customersprovide feedbacktosuppliersaboutthe outputof the process.

Process Value

ProcessValue isthe reasonthe processexists,the “why”behindthe process. Itiseasyto confuse process

outputswithProcessValue. Forexample,areportmaybe an output, butthe ProcessValue isreallyinformation

to be usedindecisionmaking. We can alsothinkof the ProcessValue asthe desiredresultoroutcome of the

process. Definingthe ProcessValue appropriatelycanopenupnew avenuesfordesignof the process.

Inputs

Inputsare itemsorinformationthe processstartswithandtransformsintooutputs. Inputscome intwoflavors:

- Items– informationorsupplies

4 Copyright 2013Craig Paxson

?

Decisions

Triggers

Triggers– Triggers“start” the process. For instance,inputstoanaccounts receivableprocessmayinclude

purchase ordersand invoices. Itisthe receiptof the invoice that“triggers”the processtostart.

Suppliers

Suppliersprovide the Inputs(materials,suppliesandinformation)foraprocessto work onand alsoprovide the

triggerthat tellsthe processwhentostart.

Activities

Activitiesare generallyeasytoidentifyusingtraditional processmappingorflowcharttechniques. Activities

may include value-addworkand non-value-addwork.

Decisions

Decisionsare made byActors andgovernwhichActivitiesoccur. A Decisionspecifieswhatneedstobe done,as

opposedtoan Activity,whichspecifieshowsomethingistobe done.

Actors

Actors are the people orsystems inaprocessthat performthe Activitiesof the process. Actorsuse resourcesto

performthe Activities.

5 Copyright 2013Craig Paxson

Resources

Resourcesare usedbyActors to performActivities. Examplesof resourcesmaybe machinery,computer

systemsorcommunicationssystems.

Outputs

Outputsare the endresultof the processand will be deliveredtothe processcustomer.

Channels

Channelsare the meansbywhichthe outputsare deliveredtothe customers.

Typical channelsinclude:

- Physical delivery

- Electronicdelivery

- In-Person

Costs

Costsare incurredbythe actors inthe process,the resourcesused,the Outputscreatedandthe Channelsused

to deliver.

6 Copyright 2013Craig Paxson

Feedback

Feedbackprovidesthe Customerwiththe abilitytomodifythe process. Feedbackcomesfromthe Customerto

the Supplierandcontainsinformationabouthow well the Outputsare meetingthe definedProcess Value.

Feed Forward

FeedForwardprovidesthe Supplierwiththe abilitytomodifythe behaviorsof the Actorsina process. Feed

Forwardmay include CustomerFeedback,informationabout future events(volume changes,forexample).

7 Copyright 2013Craig Paxson

Moments of Truth and Points of Failure

Moments of

Truth

Moments of Truth – the points at which activities or outputs touch the customer.

Points

of

Failure

Pointsof Failure –pointsin the processwhere twothe processinteractswiththe Customer,twoActorsinteract,

an Actor uses a resource, or a Decision is taken.

Points of Failure are the most likely points in the process where things can go wrong, and therefore the most

likely places for improvement.

The total numberof Pointsof Failure isa good indicator of how efficient a process is. The fewer the number of

PoF, the more efficient. We can track how much a process has improved by monitoring the number of PoFs

reduced during process improvement activities.

After diagramming the process, we should list the MoTs, PoFs, the actors involved or the decision taken.

8 Copyright 2013Craig Paxson

The Process Wastes

Once we are finishedusingthe Canvastodescribe the purpose,inputs,processandoutputsof ourprocess,we

can start innovating.Innovationisreallyagame of drivingwaste fromthe process.

We can lookat the value of the process,and the outputsandstepsusedto create it andsee there are three

typesof stepsand outputs:

A. Stepsthatdefinitely create value.

B. Stepsthat create no value,butare necessarygiventhe currentstate of the system.

C. Stepsthatcreate novalue and can be eliminated.

Of these,Band C create waste.The Japanese have termedwaste muda andcategorize itintoseventypes:

1. Overproduction:Producingmore thanisneeded,fasterthanneededorbefore needed.

2. Waiting:Idle time thatoccurs whenco-dependenteventsare notsynchronized.

3. Transportation:Anymaterial movementthatdoes notdirectlysupportimmediateproduction.

4. Processing:Redundanteffort(productionorcommunication)whichaddsnovalue toa productor service.

5. Inventory:Anysupplyinexcessof processordemandrequirements.

6. Motion: Anymovementof peoplewhichdoesnotcontributeaddedvalue tothe productorservice.

7. Defect:Repairor reworkof a productor service tofulfill customerrequirements.

We oftenthinkof waste number7(defects),butrarelythinkof the othersix.

All of these wastesare presentineveryprocess.Forexample,inmedical claimprocessingwe findmailingpaper

documents(transportation),claimsheldup waitingformore documentation(inventory),staff whoonlywork

special claims(inventory - yesstaff isinventory),time spent waitingforsupervisorapproval (waiting),checking

balancesmultipletimestosee if ithas changed(overprocessing),generatingmultipleinvoices(overproduction),

creatingelectronicandpaperrecords(overproduction) andincorrectbilling(defects).

Alternatively,we cangroupthese wastesdifferently,tomake iteasiertothinkof themacross a business

process.

People Wastes

1. AssignmentWaste –Completinganunnecessaryorinappropriate task.

2. WaitingWaste – People waitingforinformation,resourcesorapproval.

3. MotionWaste - Any movementof people whichdoesnotcontributeaddedvaluetothe productor service.

4. ProcessingWaste – completinganactivityinanon-optimal way.Anymethodtocompleteataskthat is not

optimal createswaste.

Process Wastes

1. Control Waste – Energyusedforsupervisionormonitoringthatdoesnotproduce improvementinthe

process.

2. VariabilityWaste –Resourcesexpendedtocompensate fororcorrectoutcomesthat deviate fromthe

expectedoroptimal outcome.

3. TamperingWaste – The effortrequiredtocompensateforchangingaprocessand not understandingall the

consequencesof the change.

4. Work-AroundWaste – whenresourcesare usedtocreate informal processestoreplace official processes.

5. UnevenFlowWaste – Inventorywaste inside the process –inventorythatpilesupbetweenstepsof the

process.

6. CheckingWaste – Effortusedfor inspection

7. Error Waste – duplicate efforttoreworkorreplace workthat isrendereduselessbyanerror.

9 Copyright 2013Craig Paxson

8. InventoryorWork-in-ProcessWaste –resourcesappliedtoaprocessbefore theyare required,rawmaterial

or informationthatisnotbeingused,orfinishedoutputthatisnotpassedto the customer.

Information Wastes

1. TranslationWaste – the effortrequiredtochange data,formatsand reports betweenprocessactivitiesor

actors.

2. MissingInformationWaste –effortrequiredtoremedythe consequencesof missinginformation

3. Hand-Off Waste – Effortto transferinformation,workormaterialsbetweenactors.

4. IrrelevancyWaste –effortusedto manage unnecessaryorirrelevantinformation

5. Inaccuracy Waste – effortusedtocreate incorrectinformation

So nowwe can identifythe wastes - those stepsoroutputsthatdon't contribute tothe overall value of the

process.Ournextpostwill discussasimple waytoinnovate inthe process,usingatool calledSCAMPER.

10 Copyright 2013Craig Paxson

SCAMPER

SCAMPER isan acronym usedincreativityandLateral Thinkingtostimulate creative thought. The lettersin

SCAMPER standsfor:

Substitute

Combine

Adapt/ Automate

Modify

Put toanotheruse

Eliminate

Reverse

We applythese mnemonicstothe Canvas,usingeachtriggerineach blockinthe Canvas.

For example,we canaskinthe Outputblock – can thisoutputbe Putto AnotherUse? Can we Eliminate the

outputaltogether? Orinthe Activitiesblock,canwe Combine twoactivities? Canan activitybe Automated?

The followingmatrix will explore optionsforeachintersectionof blockinthe Canvasandthe SCAMPER

trigger.

11 Copyright 2013Craig Paxson

SCAMPER / Canvas Innovation Matrix

Substitute Combine Adapt /

Automate

Modify Put to

Another

Use

Eliminate Reverse

CustomerCustomer

Is there a

Customer

whocan

better

utilize the

Output?

Can this

Customer

use Outputs

fromother

processes?

Can we

change

how the

Custome

r uses

the

Output?

Can we

skipthis

Customer

and give

the Output

directlyto

the

Customer’s

Customer?

Can the

Customergive

us a different

Inputto the

Process?

Process ValueProcess Value

InputsInputs

Can we

substitute

one type of

Inputfor

another?

Can we

combine

multiple

inputsinto

one?

Can we

modify

an Input

to be

better

used?

Can we

use an

Inputin

another

process?

Do we

needthis

Inputto

provide the

same

Process

Value?

Where does

the Input

come from?

What process

Outputisit?

Trigger

Can the

Processbe

initiated

witha

different

trigger?

If the Trigger

ismanual,

can it be

automated

(eitherthe

trigger

generationor

consumption

)

Can the

Trigger

be made

cheaper

or more

reliable?

Can this

Trigger

initiate

more

than one

Process?

Can we

eliminate

thisTrigger

and use a

different

one?

What creates

thisTrigger?

Can that

process

change?

SuppliersSuppliers

Can the

Inputcome

froma

different

Supplier?

Can one

Supplier

supply

more than

one Input?

Can we

eliminatea

Supplier

and replace

it with

something

else?

What Inputs

do we give to

the Supplier?

Can we

change those

to improve

the supply?

ActivitiesActivities

Can we

perform

the same

actionwith

a different

activity?

Can we

combine

two

activities

intoone?

Can we

automate the

activities?

Can we

change

an

activity

to make

it easier?

Can this

activity

give usa

different

result?

Can we

eliminate

this

activity?

12 Copyright 2013Craig Paxson

Substitute Combine Adapt /

Automate

Modify Put to

Another

Use

Eliminate Reverse

Actors

Can

someone

else dothis

process?

Can one

person

performthe

activitytwo

are now?

Can we

eliminate

thisactor?

Can

someone

else make

this

decision?

Can this

decisionbe

automated?

Is the

business

logicin

this

decision

correct?

ResourcesResources

OutputsOutputs

Coulda

different

output

obtainthe

same

process

value?

Can two

outputsbe

combined

and give the

same

value?

Can this

output

be

changed

to create

more

value or

lesscost?

Can the

custome

r use this

outputin

a

different

way?

Is this

output

necessary

for the

process

value?

What isthis

outputan

inputto?

Doesthat

create

possibilities

for

improvement

?

Channels

Can the

outputbe

delivered

differently

?

Doesthe

outputtake

two

different

channels?

Can those

be

combined?

Feedback

Can

feedback

be

changedto

control the

process

better?

Are there

multiple

feedback

mechanism

s that can

be

combined?

Can the

feedback

automatically

control the

process?

Can

feedback

be used

ina

different

process?

Is there

feedback

froma

different

process

that

couldbe

used?

Is this

feedback

necessary?

Is itused?

13 Copyright 2013Craig Paxson

Substitute Combine Adapt /

Automate

Modify Put to

Another

Use

Eliminate Reverse

Feed

Forward

Can feed

forwardbe

changedto

notifythe

customer

better?

Are there

multiple

feed

forward

mechanism

s that can

be

combined?

Can the feed

forward

automatically

control the

nextprocess?

Can feed

forward

be used

ina

different

process?

Is there

feed

forward

froma

different

process

that

couldbe

used?

Moments of

Truth

Points

of

Failure

Can the

same actor

performthe

two

activities?

Can one

activity

replace the

two?

Can one of

the two

activities

be

eliminated

?

Can we to the

activitiesin

the reverse

order?

As youcan see,the SCAMPERtriggersbringup manypossibilitiesforprocessinnovation. Remember,SCAMPER

shouldbe a triggerfor ideagenerationandthe matrix above isjustafew of the possible usesforSCAMPERin

the InnovationModel.

14 Copyright 2013Craig Paxson

What is the Problem?

Accordingto Masaaki Imai inhisbook“Gemba Kaizen,”everyprocessvalueisbuiltonacombinationof quality,

cost and delivery.These threecharacteristicsare notseparate,butcloselyinterrelated.Quality inourprocess

model meansthe abilityof the outputtodeliverthe processvalue. Costisthe amountof effortandresources

usedto create the processoutputand deliverittothe customer. Delivery refersto the deliveryof the correct

amountof processoutputto the customerat the righttime.

All processproblemsare relatedtoone ormore of these factors.Solvinga problemrelatedtodelivery,suchas

howlongit takesto create the output,may notbe the properapproachif the outputdoesn’tdeliverthe value

the customerneeds.

Using the Framework

Step0 – determine the “problem”withthe process.The problemwill alwaysbe avariationof Quality,Costor

Delivery.

Step1 – determine the “outeredges”of the process –the Value,Customer,SupplierandTriggers.

Step2 – map the otherblocksof the Canvasas necessary.Noteverybuildingblockisnecessary,orpresentin

everyprocessmap.

Step3 – determine all Momentsof TruthandPointsof Failure

Step4 - applythe SCAMPERtriggersto create opportunitiesforimprovement

Step5 – lookat the Wastesinthe process

Step6 – repeat.

Thiswork islicensedunderthe Creative CommonsAttribution-NonCommercial-NoDerivatives4.0International

License.Toviewacopy of thislicense,visithttp://creativecommons.org/licenses/by-nc-nd/4.0/.