Your Intelligent Manufacturing Solution for Industry 4.0

Blog: The Tibco Blog

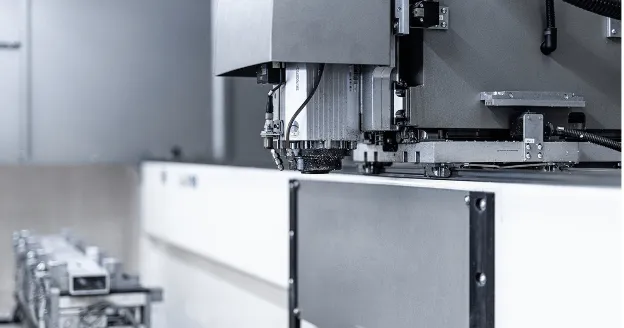

Agility is critical in the modern manufacturing environment. Industry 4.0, the label attached to automation and data exchange trends, means that savvy manufacturers leverage cloud-based technology and cyber-physical systems to operate a nimble, smart factory.

Are you missing a critical link in your journey to optimization for Industry 4.0? If so, it’s time to consider an intelligent manufacturing solution to help you gain supply chain efficiencies and compete in the marketplace. TIBCO’s Manufacturing Intelligence solution enables an agile, smart factory.

Automate for Greater Efficiency

Process automation is essential to Industry 4.0. When you use data to power intelligent automation, you reduce manual processes, increase productivity, refocus your workers on more value-added tasks, and enable better organization-wide decision making. When your business can make intelligent decisions, your people and resources can be allocated optimally to minimize machine and equipment downtime.

Integrate Data Seamlessly

Manufacturers collect, store, and use data across various machines, systems, and data repositories. To optimize efficiency, this data needs to be unified for holistic access. The challenge is that there are countless protocols involved in connecting the data across your operations. It takes cloud-based intelligence, data mining, and analytics to connect the various data stores.

The TIBCO Connected Intelligence platform seamlessly integrates data across processes, equipment, and Industrial Internet of Things (IIoT) devices, intelligently unifies that data for greater access and control, and confidently predicts the future to help reduce costs, improve operational efficiencies, and increase profitability.

Increase Process Optimization and Reduce Defects

Manufacturers aim for consistent production processes, and intelligent automation enables them. Quality control (QC) is used to identify defects or flawed products, but QC takes time and resources. It is better to have consistent production that ensures each product is flawless.

Reducing or eliminating inconsistencies saves time and resources in quality control. It also lowers defect rates on products delivered to buyers. Artificial intelligence (AI) models allow you to combine historical and real-time supply chain data to find quality issues early. The AI learns from automated root-cause analysis and other processes to dynamically improve quality consistency.

Create a Resilient Supply Chain

Supply chain optimization is vital to competing in modern distribution channels. Buyers throughout the distribution channel rely on on-time delivery of products. Any delays or bottlenecks in production and distribution give your competitors an advantage in filling orders.

Industry 4.0 and automated intelligence enables proactive responses to supply chain changes. Instead of manually recognizing demand changes or problems, the data reveals inventory insights and enables you to optimize transportation and logistics.

Support Regulatory Compliance

Many manufacturers face significant industry regulations that impact production processes and products. Industry 4.0 automation enables greater efficiency and accuracy in meeting compliance by reducing opportunities for human error, improving audit and tracking information, and providing analytics that helps identify potential compliance issues before they arise.

Maximize Revenue and Profit

Optimized revenue and profit are the net results of automation and accuracy through manufacturing intelligence. You can maximize resource utilization to deliver products on time while also minimizing costs. Automation also enables agility as manufacturers scale to accommodate new customers or new products being brought to market.

Your Agile Industry 4.0 Solution

Industry 4.0 is foundational to success in the current manufacturing ecosystem. The benefits of automation through holistic data insight, process optimization, supply chain resilience, and industry compliance are vital.

TIBCO is a leader in Industry 4.0, providing manufacturing intelligence for the modern smart factory. Learn more about manufacturing intelligence for your digital factory today.

The post Your Intelligent Manufacturing Solution for Industry 4.0 first appeared on The TIBCO Blog.