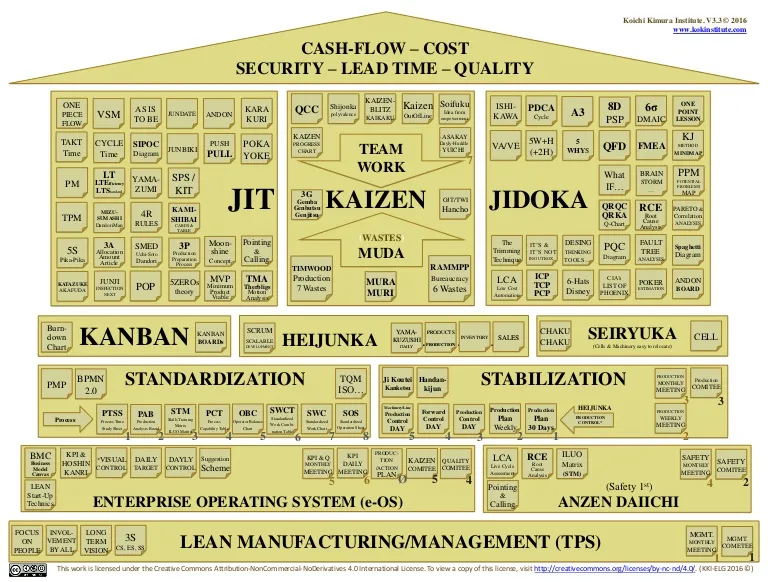

THE HOUSE OF LEAN MANUFACTURING / MANAGEMENT (TPS) V3.4

Description

FULL A1 RESOLUTION. KOICHI KIMURA INSTITUTE. PDF FULL A1 RESOLUTION

Transcript

HEIJUNKA ……. .……… ………

CASH-FLOW – COST

SECURITY – LEAD TIME – QUALITY

JIT JIDOKA

STANDARDIZATION STABILIZATION

ENTERPRISE OPERATING SYSTEM (e-OS**)

LEAN MANUFACTURING/MANAGEMENT (TPS)

TEAM

WORK

(WASTES)

MUDA

PDCA

Cycle

FMEAPOKA

YOKE

QFD

A3

QRQC

QRKA

Q-Chart

5

WHYS

ISHI-

KAWA

8D

PSP

· IT’S &

· IT’S NOT

· IN/OUT BOX

ONE

POINT

LESSON

BRAIN

STORM

…

6σ

DMAIC

KJ

METHOD

MINDMAP

POKER

ESTIMATION

ANDON

BOARD

PM

TAKT

Time

TPM

ONE

PIECE

FLOW

ANDON

CYCLE

Time

JUNJI

INSPECTION

NEXT

5S

Pika-Pika

PUSH

PULL

ICP

TCP

PCP

VSM

SCRUM

SCALABLE

DEVELOPMENT

SMED

Uchi-Soto

Dandori

·ASAKAY

Dayly-Huddle

·YUICHI

POP

4R

RULES

3A

Allocation

Amount

Article

PTSS

Process Time

Study Sheet

QCCJUNDATE

JUNBIKI

TIMWOOD

Production

7 Wastes

KAMI-

SHIBAI

CARDS &

TABLE

MIZU-

SUMASHI

DandoriMan

KAIZEN-

BLITZ

KAIKAKU

Shijonka

polyvalence

Soifuku

Idea from

empowerment

5ZEROs

theory

KATAZUKE

AKAFUDA

SPS /

KIT

6-Hats

Disney

LT

LTEfficiency

LTStandard

KANBAN SEIRYUKA

(Cells & Machinery easy to relocate)

PRODUCTS

PRODUCTION

5W+H

(+2H)

INVENTORY SALES

YAMA-

KUZUSHI

DAILY

MURA

MURI

(Safety 1st)

ANZEN DAIICHI

PQC

Diagram

Kaizen

OutOfLine

3G

Gemba

Genbutsu

Genjitsu

*VISUAL

CONTROL

DAILY

TARGET

DAYLY

CONTROL

PRODUC-

TION

/ACTION

PLAN

KPI &

HOSHIN

KANRI

BMC

Business

Model

Canvas

AS IS

TO BE

KAIZEN

PROGRESS

CHART

PPM

POTENTIAL

PROBLEMS

MAP

FOCUS

ON

PEOPLE

INVOL-

VEMENT

BY ALL

LONG

TERM

VISION

KPI

DAILY

MEETING

KPI & Q

MONTHLY

MEETING

FAULT

TREE

ANALYSIS

PARETO &

Correlation

ANALYSIS

RCE

Root

Cause

Analysis

TQM

ISO…

Suggestion

Scheme

QCC

What

IF…

SAFETY

MONTHLY

MEETING

RCE

Root

Cause

Analysis

BPMN

2.0

PMP

PRODUCTION

MONTHLY

MEETING

PRODUCTION

WEEKLY

MEETING

QUALITY

COMITEE

SAFETY

COMITEE

Production

COMITEE

DESING

THINKING

TOOLS…

MVP

Minimum

Product

Viable

MGMT.

COMETEE

MGMT.

MONTHLY

MEETING

3S

CS, ES, SS

KAIZEN

COMITEE

1

2

3

45

1

2

3

45 6

CHAKU

CHAKU

YAMA-

ZUMI

KARA

KURI

LCA

Low Cost

Automation

3P

Production

Preparation

Process

OJT/TWI

Hancho

CELL

LCA

Live Cycle

Assessment

Burn-

down

Chart

Ji Koutei

Kanketsu

ILUO

Matrix

(STM)

PCT

Process

Capability Table

SWCT

Standardized

Work Combi-

nation Table

SOS

Standardized

Operation Sheet

PAB

Production

Analysis Board

STM

Skills Training

Matrix

ILUO Matrix

OBC

Operator Balance

Chart

SWC

Standardized

Work Chart

KANBAN

BOARDs

1 2 3 4 5 6 7 8

Handan-

kijun

Process

Spaghetti

Diagram

SIPOC

Diagram

Production

Plan

30 Days

1

Production

Plan

Weekly

2

Production

Control

DAY

3

Forward

Control

DAY

4

Machinery/Line

Production

Control

DAY

5

PRODUCTION

CONTROL*

7

RAMMPP

Bureaucracy

6 Wastes

KAIZEN

HEIJUNKA

LEAN

Start-Up

Technics

CIA’s

LIST OF

PHOENIX

Moon-

shine

Concept

TMA

Therbligs

Motion

Analysis

This work is licensed under the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/4.0/. (KKI-ELG 2016 ©)

Pointing

&

Calling

Pointing

&

Calling

The

Trimming

Technique

Ø

VA/VE

Koichi Kimura Institute. V3.4 © 2016

www.kokinstitute.com

THE ENTERPRISE OPERATING SYSTEM (e-OS**)

COMPANY POLICY

HOSHIN

KANRI

PLANNING

FINANCIALs

PLANING &

COST /u

KPIs &

TARGET

PLANNING

ACTION PLAN

FOR

ACHIEVING

DEPARMENT

BUDGET

DEPARTMENT

BUDGET

PRODUCTION

PLAN

MONTH,

WEEK, DAY

1

DEPARTMENT POLICY

10

DAILY

FOLLOWUP

& GRAPH

SYSTEM

ACT OF

PRODUCTION

Throughout

PRODUNTION

PLAN

DAILY

TARGET &

VISUAL

CONTROL

11

1. QCC + Suggestion Scheme: By ALL

2. Follow-Up in meetings:

Monthly: Management

Monthly: Production

Monthly: KAIZEN + Safety

Monthly: KPIs Targets + Quality

Weekly: Production

Weekly: QCCs

Daily: KPIs Targets (ASAKAY)

Daily: Graph System

Daily: Training

JIT: QRQC/QRQA (PDCA + Standardization)

3. Every Lean Tools: 5S, 4R, TPM, etc.

14

DEPARTMENT

SALES

PLANNING

SALES

PLANNING

MANPOWER &

EQUIPMENT

PLANNING

& Feed Back

KPIs

Planning

2 3 4

ANNUAL

DEPARTMENT

PLANNING

DEPARTMENT

PRODUCTION

PLANNING

6

5

7 8

DEPARTMENT

BUDGET

& Feed Back

9

ACTION

PLAN

12 13

LINE / MAN-MACHINERY POLICY

KAIZEN17

ANNUAL

DEPARTMENT

PLANNING

15 16

Koichi Kimura Institute. V3.4 - ELG © 2016

www.kokinstitute.com

This work is licensed under the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/4.0/. (KKI-ELG 2016 ©)

PDCA + Standardization

PDCA + Standardization

12

6

ACHIEVING THE BASIC CONDITION FOR KAIZEN & LEAN-TOOLS APPLICATION