The Box….the undisputed heavyweight of supply chain costs

“…The size of the box didn’t matter. Today it does…”

FedEx and UPS changed the game by applying dimensional weight to the cost of the delivery back in December 2014. At that time, I predicted this could increase the cost of a parcel delivery by 30 percent. Here’s a link to the story posted by Logistics Viewpoint. Let’s fast forward to the present.

Shipping giant UPS announced in October 2015, another rate increase of 4.9 percent for ground freight. The reason? Changing demand and higher costs. Of course, the e-commerce business continues to disrupt the delivery process.

The third flaming wheel to disruption and price increases is the addition of third party vendors. The large carriers such as FedEx and UPS are charging handling costs related to third party vendors which adding yet another cost. This surcharge is a new line item in the total shipping cost. Supply chain leaders in all markets that are tied to either parcel deliveries, commercial business, or end consumer last mile channel, will be affected.

The new norm

Prior to January 2015, shipping costs were calculated based upon gross weight. The size of the box didn’t matter. Today it does. Now, shippers are charging for their floor or deck space on the truck, plane, or ship.

As of today, shippers are no longer concerned about the next day delivery request. The new norm is same day deliveries. To add even more complexity, Sunday deliveries are becoming a common offering from even the United States Postal Service.

Hence, space onboard trucks, planes, and ships now comes at higher premium. So-called, low-density packaging – the combined weight and dimensions of the box along with the shipped item inside the box, is no longer the measure.

Now, the contents of the box, as well as the box itself, is being reconsidered, weighed, and measured. Shippers are charging a premium for their challenged floor and deck space. Therefore, every inch and every ounce of the shipping box or package along with its contents are charged to the customer. Thus, the idea of Dimensional Weight Shipping was born.

Revenue impact on parcel business

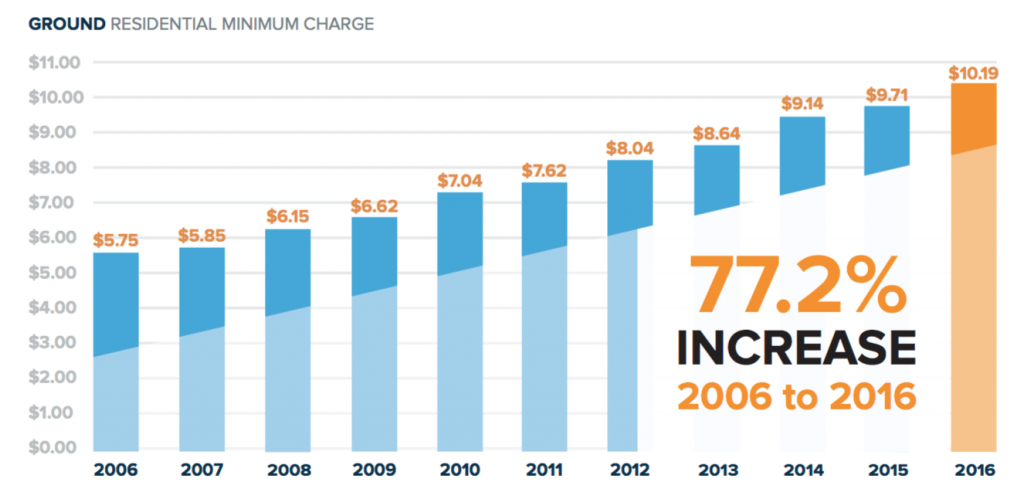

FedEx announced ground business revenue of $4.41 billion, up 30 percent from last year’s $3.39 billion. This performance is on target in terms of what I expected would be the top-line growth plus adding in the continued trend of more e-commerce shipments. According to www.lojistic.com, ground tariff rates for UPS and FedEx have increased 79.2 percent over the last 10 years. This increase does not even include the dimensional pricing changes. Understand though that the carriers’ contractual commercial rates with shippers may be different case by case. The largest price increases are for the end consumer door deliveries given the increased demand of e-commerce shipping. The chart below illustrates the historical increases over the past decade.

Historical increases over the past decade.

The supply chain is the heartbeat of your company

Given the continued annual increases, this should be a wake-up call to supply chain managers who ship large volumes of parcel packages. The shippers affected the most are food, medical device, consumer good personal care, food, and pharmaceutical companies. Why? These companies generally ship high-value, high-volume products or, require cold-chain capabilities. The margins are significant for some of these industries but supply chain performance has not received priority attention. Given the eroding margins for these shippers, leadership is just now understanding the value of the supply chain. The supply chain is the heartbeat of the company and without intentional investment in this function, margins will continue to erode.

Here are some of the changes that have taken place since the implementation of dimensional pricing.

- Shippers have modified their packaging

- Some have renegotiated contract terms with the carriers

- Some have decided to switch current carriers or added other carriers

These changes do help to limit or contain the impact of DIM pricing. Only a few are looking at a more sustainable solution that does not increase in price every year. Carriers will always find ways to support price increases, so changing and renegotiating with carriers is a necessary requirement in the transportation world.

Solution? Cartonization optimization.

The real solution that will provide savings and sustain cost avoidance is cartonization optimization. Identifying ways to place more pieces into the same box is a very simple yet high impact way of addressing the problem. Volume optimization using technology to identify the right box that can hold the materials is critical to parcel shippers and the LTL business collectively. In the LTL business, freight rates are determined by class, weight, pick-up and destination zip codes and any other additional services required. Today, the volume size will play a considerable role in determining the cost. Since a larger volume means a greater dimensional weight, you should aim to package as many goods into a box or on a pallet as possible so that it does not exceed the actual weight.

Parcel Box Optimization

Companies like L’Oreal in Europe are using parcel box optimization technology to ensure as many items are placed in a box as possible and that the optimal box size is selected. Advanced and executional cartonizing results in quantifiable reduction in parcel delivery cost, increased labor efficiencies and precise dimensional pricing. Using box optimization technology has demonstrated up to 15 percent improvement in box utilization, 40 percent cost avoidance, 20-30 percent improvement in pick/pack labor efficiencies and a reduction in carbon footprint by using less corrugate.

Further Reading

Forbes.com: Dimensional Weight Pricing Doesn’t Just Lead to Higher Shipping Costs, It Leads To Higher Costs In The Warehouse

The post The Box….the undisputed heavyweight of supply chain costs appeared first on This Complex World.

Leave a Comment

You must be logged in to post a comment.