Should we focus on BPI comimg out of an economic Recession?

Blog: Biz-Performance, David Brown

This question in the Blog Title was posed by one of the readers. It never ceases to amaze me how we only react to external factors after they have happened. In my humble opinion we should always be looking to improve the Business Processes within our Organisation. Business Process Improvement is not something we do to prevent an event from happening again as it is very seldom that an identical event happens more than once. We need to be vigilant when monitoring our processes and take the necessary steps to ensure we can identify quickly an adverse occurrence and be resourceful in correcting it.

I read an article which was published during the recession; unfortunately I cannot remember who wrote the article, defining a number of rules on how to handle the recessionary situation:

There are many methodologies for analysing process and activities within an organisation with the aim to continuously improve the performance of the business and reduce waste. One of the early advocates was Edward Deming who modified Walter Stewarts’ concept of Plan, Do, and See to create the Deming Cycle (PDSA). This concept has been utilised and modified by many, to create continuous improvement cycles. There are many different methodologies available for continuous process improvement:

There are many methodologies for analysing process and activities within an organisation with the aim to continuously improve the performance of the business and reduce waste. One of the early advocates was Edward Deming who modified Walter Stewarts’ concept of Plan, Do, and See to create the Deming Cycle (PDSA). This concept has been utilised and modified by many, to create continuous improvement cycles. There are many different methodologies available for continuous process improvement:

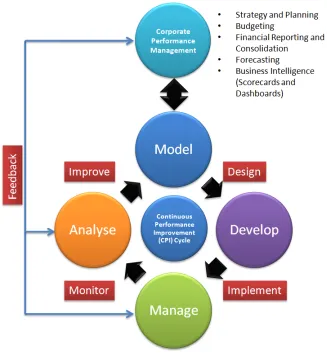

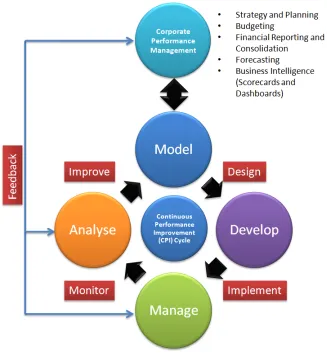

In one of my earlier Blogs I did touch on the Business Process Improvement Cycle (BPM is an essential part of a Continuous Performance Improvement Project). This is also an adaptation of the Deming Cycle. I would also state that in some cases, and this would depend on extent of the changes to the Business Model, it may be better to create another division and re-design the Business Processes from the beginning.

I read an article which was published during the recession; unfortunately I cannot remember who wrote the article, defining a number of rules on how to handle the recessionary situation:

- Rule 1: Protect Your Best Customers, Products & Channels

- Rule 2: Refocus the Customer Experience Around the Value Equation

- Rule 3: Sweat Your Customer Management Assets

- Rule 4: Cut Non-value-adding Costs while Protecting Value

- Rule 5: Support & Incentivise Staff to Deliver Value

- Rule 6: Focus on the Long-term while Supporting the Short-term

There are many methodologies for analysing process and activities within an organisation with the aim to continuously improve the performance of the business and reduce waste. One of the early advocates was Edward Deming who modified Walter Stewarts’ concept of Plan, Do, and See to create the Deming Cycle (PDSA). This concept has been utilised and modified by many, to create continuous improvement cycles. There are many different methodologies available for continuous process improvement:

There are many methodologies for analysing process and activities within an organisation with the aim to continuously improve the performance of the business and reduce waste. One of the early advocates was Edward Deming who modified Walter Stewarts’ concept of Plan, Do, and See to create the Deming Cycle (PDSA). This concept has been utilised and modified by many, to create continuous improvement cycles. There are many different methodologies available for continuous process improvement:- Six Sigma

- Kaizen

- Lean Manufacturing

- Total Quality Management

- Toyota Production System

- Theory of Constraints etc.

In one of my earlier Blogs I did touch on the Business Process Improvement Cycle (BPM is an essential part of a Continuous Performance Improvement Project). This is also an adaptation of the Deming Cycle. I would also state that in some cases, and this would depend on extent of the changes to the Business Model, it may be better to create another division and re-design the Business Processes from the beginning.