Process Mining Interview with Joris Keizers

This is a guest article by Ren Peter from Warehouse Totaal and by Joris Keizers from Veco. The article previously appeared in Dutch here. If you have a guest article or process mining case study that you would like to share as well, please contact us via anne@fluxicon.com.

Before he knew it, he was one of the three finalists. “Yes, and once you’re on stage, you obviously want to win as well.” In April 2018, Group Operations Manager Joris Keizers (45) became Logistics Manager of the Year with the application of a data analysis technique called Process Mining. Jury chairman Ren de Koster on this technology: “We think this is a fantastic tool that you can use in many organizations.”

“You are looking for the gold in a smart way.” With ‘gold’ Keizers is referring to the insights about where improvements can be made in the logistical process.

How do you apply such a process mining tool and what practical tips can be given to warehouse managers about it?

Congratulations on the title. How did you experience the election night?

Keizers: “I enjoyed it. The title is a very nice recognition for the work you do. Everyone in the company was also very happy. When I entered my office everything was decorated. Then you realize that it is indeed quite special what we have achieved together. “

Did you think you would have a chance to win the title right from the start?

“Well, I saw from the beginning that all finalists had a very different profile, all with their own strong points. We are not a company with a large warehouse where trucks drive on and off continuously. We have a tiny 30 square meter warehouse. At the end of the day, a courier comes by to collect everything in one go.

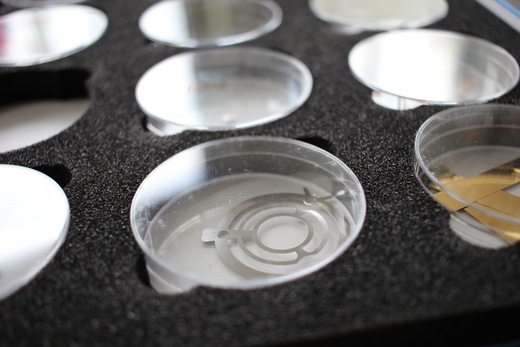

Here in Eerbeek we make very small precision products from nickel, such as the sight of a shotgun, atomizers for medicines, or coding discs for robot arms. Only at the very end we see the result of the production process.

Therefore, it is very important for us to have as short as possible lead times. In order to achieve this, I started to study the application of Big Data & Data Science in the supply chain.”

Do you think that too little work is being done with Big Data in internal logistics?

“Absolutely. If you see what kind of data is already being collected in automated warehouses, I think there is still too little done with it. With every scanned barcode a timestamp is recorded along with a lot of other useful information: Who does what & when?

When you hear Big Data you may perhaps only think of big tech companies like Amazon, Google and Facebook that collect more data than they can process. The trick is to apply smart methods to get things out of the data based on which you can actually do something.

Many managers arrive with an ISO book when you ask how their processes are running. But that is only how it was once invented and does not guarantee that it will happen like that in the workplace. It obscures your view of the performance of the entire chain if you look no further.”

Is process mining such a smart method?

“Yes, it is a technique that allows you to make use of the available data in a smart way. It makes the performance of your process transparent.

With process mining, I can characterize all operations within our company, stored by our ERP system, with three different parameters. First the number of the production order it belongs to, second the workstation where it was executed, and thirdly when exactly the operation happened. With one production order many more workstations are involved than with others.

By letting smart algorithms have a go at this data, insightful patterns can be discovered. I can see which workstations always or never follow each other. It gives real insight into the problems in your business processes. The technique can show you how your process really works and whether it deviates from how it was designed in the beginning.”

Is it still too complicated for many logistics companies to apply?

“Perhaps it is also that the need is not really felt enough to do something with it. Yet the intralogistics world is very well suited to leverage Big Data. People who work there think in processes. On the other hand, it is not always easy: You can sometimes get dozens of different results out of your analysis.

I think that in internal logistics faster machines and robotics are mainly thought of instead of processes as a whole.”

How do you convert that ton of data into practical tools?

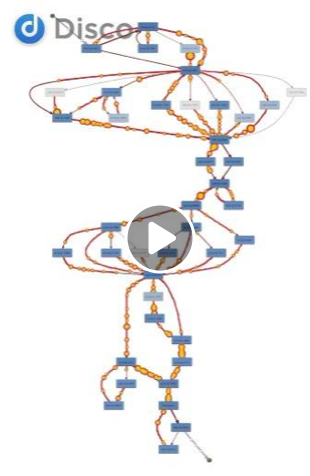

“I transfer the data from our ERP system to the process mining software of ‘Disco’. With the help of the algorithms from this program, the production orders are analyzed. I can run a replay of a certain time period and see through an animation how the orders run through the factory.

Where I see a delay, I can filter which orders this concerns. In such an animation I saw that almost all orders go through our measuring room. When I showed it to my team, it became a lot more insightful.

It appeals much more to the imagination than a graph or statistic. It communicates much easier, so you also appeal to a broader solution area for employees. “

Where are the points for improvement?

“After such an analysis you can look much more focused at where you can improve. That is often not in the speed of machines, but especially in displacements, administrative preparation, waiting time, etc.

So you can put a lot of time into making machines faster, but then I may be optimizing only 20 percent of the whole process. So, I can better look at that 80 percent, trying to shorten the waiting time.”

Where is the biggest challenge for warehouse managers who want to get started with process mining?

“People with an analytical background can learn this fairly quickly. You can easily go through an order picking process through the software to see where the bottlenecks are.

An important condition is that you have as much unity as possible in the type of data that you import. In the future, I expect that such plugins for analysis can be integrated into WMS and ERP systems.

My message to logistics managers is also to look for new techniques to apply. Process mining is just one of the tools that you can use.”

You can download this interview as a PDF here for easier printing or sharing with others.

Leave a Comment

You must be logged in to post a comment.