Optimizing Operations with Blockchain in the Semiconductor and Electronics Manufacturing Supply Chain

Blog: The Tibco Blog

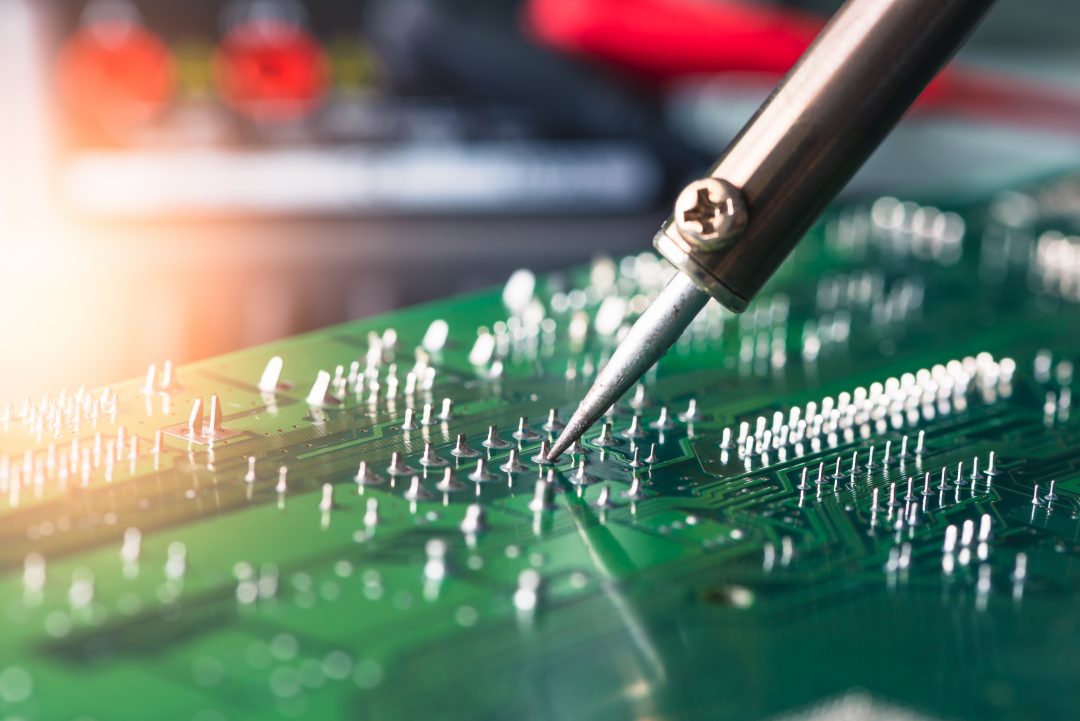

Semiconductor, electronics and equipment manufacturers today face a number of logistics and supply chain challenges that could be overcome by systems providing a secure, tamper-resistant, single source of truth. One obstacle is data security barriers between suppliers, shippers, manufacturers and test houses, an impediment to achieving optimal product quality and regulatory compliance. Additionally, inefficient and inadequate processes for tracking goods make it more difficult to isolate shipping problems, track faulty parts and verify product authenticity. Counterfeiting has become a serious problem that costs US-based semiconductor manufacturers $7.5 billion annually.

How blockchain can help

Blockchain functions can help alleviate many data sharing pain points in manufacturing. Blockchain’s distributed functionality, bundled security measures, and associated features such as smart contracts have the potential to help manufacturers quickly trace goods, manage records transparently, and automate supply chain processes and payments. No isolated blockchain platform would solve all of these problems on its own. But, when combined with other solutions and applied to particular use cases, blockchain has the potential to optimize operations and foster an environment of trust and collaboration among consortium members.

Three core features of blockchain make it a valuable technology for manufacturing:

- Distributed and immutable system of record. With a distributed system of record in the blockchain network, there is no “central” data store controlled by one organization. The distributed ledger provides all participants with a view into the data, thus increasing transparency, data distribution timeliness, information sharing, and data access. Security also improves as there is no single central data store open to external attacks. Once data is inserted onto the chain, it cannot be easily changed.

- Security and Trust. Blockchain integrates best-of-breed cryptographic mechanisms to guarantee the digital identity of the network participants and secure the privacy of the data stored to enable role-based data access. It brings trust to a potentially trustless environment without the need for a centralized third party.

- Smart Contracts. Smart contracts are embedded business logic that can be added to a blockchain. They enable the automation of many processes and the secure handling of contracts.

Example use cases

In each stage of manufacturing, blockchain could be applied in a variety of use cases to expedite processes and alleviate security issues. A few examples that merely scratch the surface of what may be possible follow.

In pre-production, manufacturers may implement blockchain solutions for Collaborative Planning, Forecasting, and Replenishment (CPFR). These systems monitor inventory levels, enabling suppliers to replenish supplies before they run low. The expensive, proprietary B2B networks used today could be replaced with blockchain as the common sharing protocol, using non-proprietary or public networks.

Suppliers may also combine blockchain with IoT sensors on shipping containers to provide a tamper-resistant record of shipping conditions. This could be used to verify that temperature and humidity tolerances for chemicals and equipment have not been exceeded during transit from the supplier.

The identity and materials in components and subcomponents of manufacturing equipment could be collected on a blockchain to verify compliance with environmental and health regulations.

During production, a manufacturing process machine can be registered on a blockchain with a unique identity; its performance and maintenance history can be recorded. A maintenance service provider could then be automatically notified, via a smart contract, when a predictive maintenance alert is written, allowing repair of machines before they fail.

In the distribution stage, customers could search the ledger for a product’s complete history, reducing counterfeiting and solidifying the origin of properly sourced goods. When a faulty product is identified, the manufacturer may search the ledger to quickly locate the supplier or bad test results and alert all receivers of the defective product.

Conclusion

With blockchain, manufacturing can become a more collaborative process among suppliers, manufacturers, and customers. Blockchain can help streamline the supply chain and inventory replenishment, improve tracking and regulatory compliance, and reduce counterfeiting.

Augmenting blockchain with IoT enables use cases like predictive maintenance and monitoring of goods during transit. Blockchain is not yet mature and its business value still needs to be proven. However, it is poised to help manufacturers decrease costs and fraud, and provide customers with faster, more secure delivery, increased visibility, and consistency.

More resources on blockchain and manufacturing

TIBCO is an active member of SEMI’s Smart Manufacturing Technology Community, which hold regular meetings on this and other topics. Join now to get regular updates.

For more information on blockchain use cases in manufacturing, please see these resources.

- Read this Whitepaper: Blockchain and Manufacturing: A Match Made in the Factory

- Watch this Webinar: Blockchain and Manufacturing – A Match Made in the Factory

- Visit the TIBCO Blockchain Solutions page

Keywords: blockchain, data security, smart manufacturing, counterfeit, fraud, supply chain, semiconductor, electronics

This article first appeared on SEMI.org.

Leave a Comment

You must be logged in to post a comment.